For many companies, tube polishing machines are an important part of their operations. They are used to keep products looking shiny and smooth, an appearance needed for many items that the company markets. Tube polishing a method where tubes are use tend to have little affects of rough spots in surface which not look good and not make for ready made. Moreover, the traditional methods of tube polishing were very time-consuming and required a lot of effort. In those days polishing would be done by hand and it took a long time, was hard work and mistakes could easily occur. Enter new machines, ones that in making this process easier and faster for everyone somehow still feel... organic, if you will.

Tube polishing machines are designed to aid businesses in saving money and doing better work fast/accurately. These machines are designed to smooth all tubes of different sizes and cross-sections simply and productively. BQ Guy: They are incredibly good at making every tube identical. - that is crucial for QA purposes These days, Typically humans end up making mistakes and leaving an uneven finish because there will be no need for people in now to polish anyways by hand. With this there is no need for the businesses to send many mails as all these will be done by machines which saves time and workload of other task.

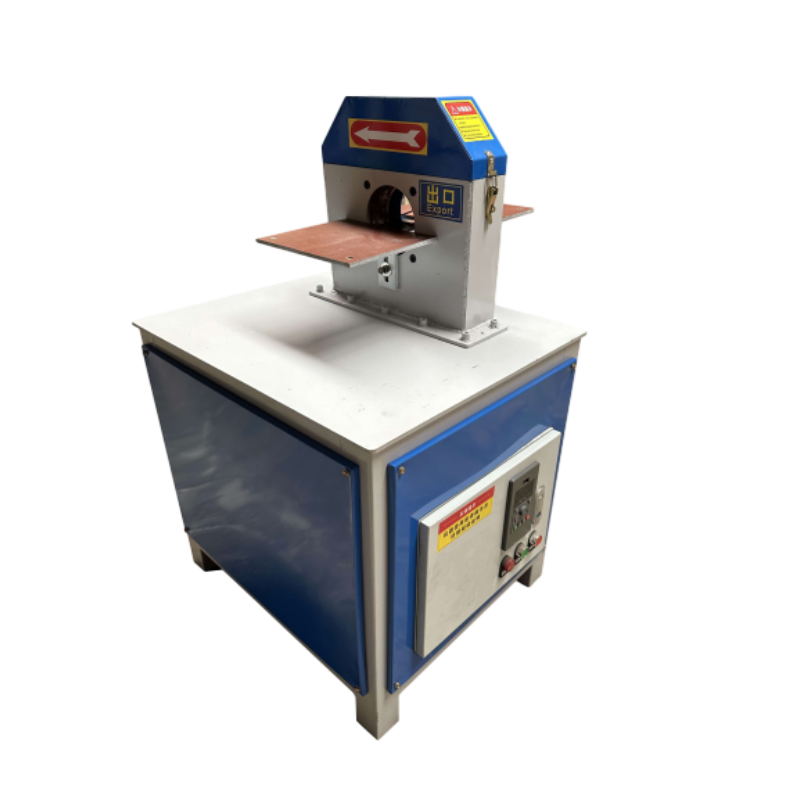

The tube polishing process is made even simpler by automatic tube polishing machines. These machines are designed to handle the grinding work with very limited additional manpower requirements. In other words, the machines are being used to sand tyres off tubes while workers focus their effort elsewhere. Designed to do this job faster and better than you or I ever could, the automatic machines ensure that all of those tubes have a lovely uniform finish - without need for human intervention. It is not a waste of time and the end products are much better.

This new tube polishing technology has revolutionized the way things are polished in many industries. This technology far less effective than any other kind one would expect, in and provides faster yet responds well better results. The machines can prepare tubes to a high standard of quality so that each individual tube is polished correctly. They are fast too, so businesses can hone ever spring in no time. This enables them to scale up their production capabilities more efficiently, and meet customer demand in a systematic manner.

There are a number of important factors that need to be considered by businesses when they seek an appropriate tube polishing machine for their specific requirements. One of the foremost things they need to ponder on is the tube size and shape that are going to be polished. Again, tubes are different in the machine from one tube to another. Feature We Got Turbo Fueled; Here Is What We Need To Keep The Charge Coming0 They need to consider the number of tubes they polish a day on average, as well how sparkly smooth they want it at the end. The durability and strength of the machine, as well as how easy it is to take care of long-term.

factory covers area 7500 square meter, five excellent designers 22, 22 senior engineers, 65 workers. factory provides OEM ODM services ability customize samples. Customization samples can done tube polishing machine days.

experienced tube polishing machine team provide with best transportation option, door door delivery sea express. Pre-sales online 24 hours day service after-sales service readily available you.

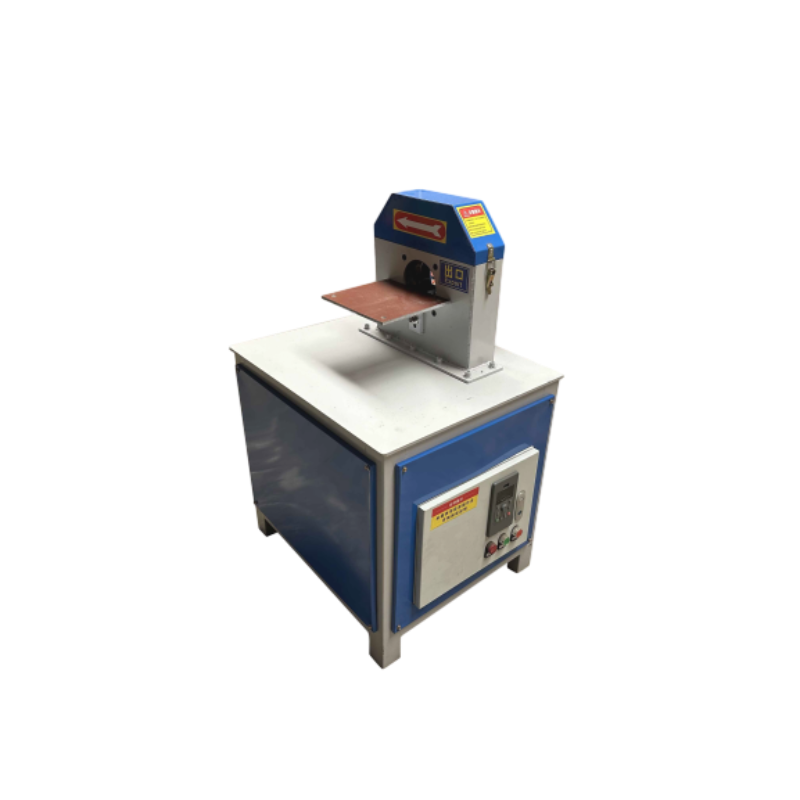

Each machine tube polishing machine, company strict quality inspection department. Every machine pass 3 times tests delivery. regular inspection process assures each machine operating efficiently customers receive good promise 2 years quality warranty every customer there no man-made damage, provide customers free equipment mail technical support should machine function expected, promise replace new machines free.

machines been certified meet ISO 9001 CE certificates. offer products highest quality tube polishing machine prices.

ONLINE

ONLINE