Did you ever notice the way metal looks when its old and rusty That does not sound cool right? But what if I told you there is a way to make this shiny new once again? This is where you will need the assistance of a particular machine known as vibratory polishing machine.

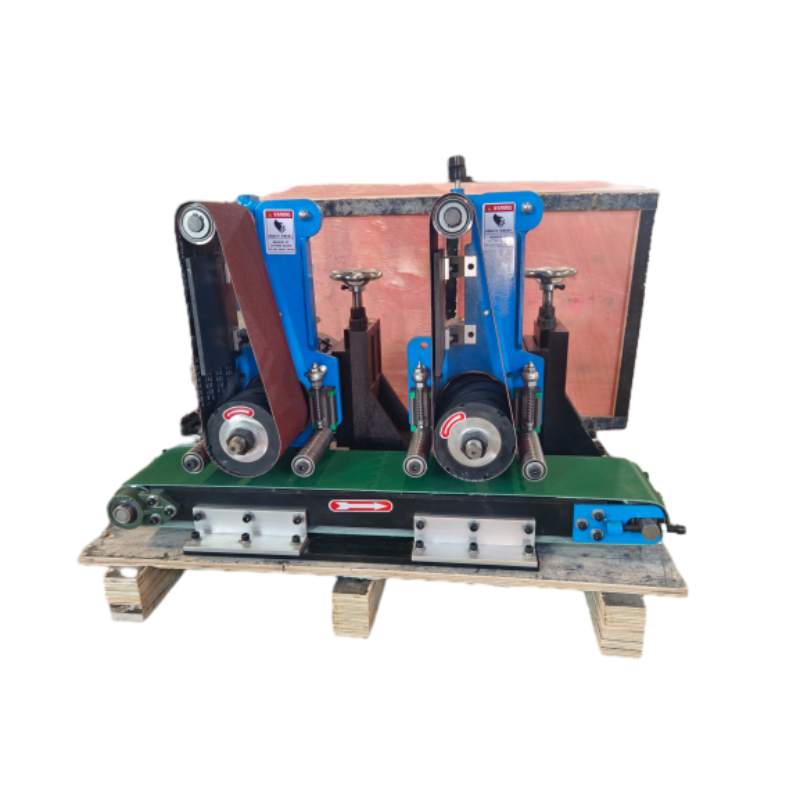

The vibratory polisher is simply a machine that moves metal parts and polishing media (balls) rapidly in the finish bowl. It will shake the parts and this way we can polish our metal surface into bright one. Clearcoat Circuitogen is designed to remove defects that can be caused by the machine polishing process, rough spots that machines may miss leaving a much better finish in terms of flatness and consistency on metal surfaces.

Really, when we say "easy," it means that vibratory polishing machines are made for working large batches of metal parts at once. This machine allows you to polish a large amount of metal pieces at once without doing each piece separately. This will save much time and effort.

This goes one further by, as a result of the use of a vibratory polishing machine meaning that all metal parts appear exactly like another. Each piece is polished in the same way so you can get that beautiful shine on every single one. Basically, you make it so that maybe some of the pieces do not have to be a little bit better than other ones.

Ceramics are the most popular and are good for complex or intricate metal pieces. Plastic: These soft surfaces are excellent for polishing softer metals, which they cannot scratch or damage. These are steel materials that use stainless and which should be strong enough to remove large bumps or burrs. Finally, organic finishing materials can be applied to all nonferrous metal surfaces as a final touch.

The shake is done by a unique motor that moves the bowl in an exact method. This shaking action causes the polishing materials to move around andosculate with metal surfaces. This rubbing action is what leaves the metal smooth and shiny.

The size and shape of the polishing mediums that are another essential role in configuring them to work with metal. However, the level of abrasiveness is still at variance from one type of polishing material to another. Which way is the right one for you to use will depend on how clean yoiu want your metal, especially after that obligatory polishing.

experienced sales team provide you most suitable transportation method delivery door sea express. vibratory polishing machine online pre-sales service after-sales service accessible customers.

vibratory polishing machine machinery is passed ISO 9001 CE certificates. offer products highest quality affordable prices.

offer 2 year guarantee quality each customer. If there no human-made damages, will provide mail accessories technical support, as well should machine not function, we'll vibratory polishing machine no cost.

factory covers area 7500 square meter, five excellent designers 22, 22 senior engineers, 65 workers. factory provides OEM ODM services ability customize samples. Customization samples can done vibratory polishing machine days.

ONLINE

ONLINE